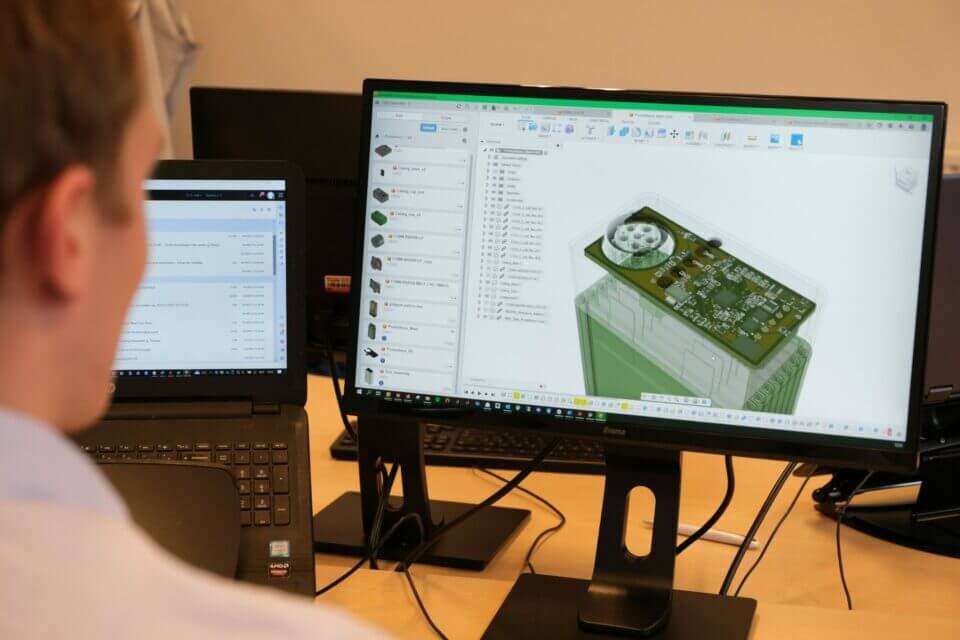

From SolidWorks to the shop floor — make it real.

Before You Hit “Apply”

Tulip Tech isn’t a place where you just make drawings all day. We’re building the future of flying machines — drones and electric aircraft — by reinventing the batteries that power them. That means housings, structures, and assemblies that are light, strong, and manufacturable. It’s ambitious, fast-moving, and sometimes messy work.

We don’t have layers of management, polished design manuals, or decades of mechanical standards lying around. You’ll be the one who makes things work: turning CAD into real parts, fixing problems in the workshop, and designing components that survive heat, vibration, and assembly.

We’re small, hands-on, and serious about what we’re doing. If you thrive on solving real-world problems, collaborating across disciplines, and making designs that actually get built — you’ll fit right in.

Your Mission

We’re looking for a Mechanical Engineer who combines design skills with a hands-on, no-bullshit mentality. Someone who doesn’t just model parts, but builds and breaks them until they’re right.

You’ll design housings, fixtures, and assemblies that can be manufactured reliably. You’ll prototype with CNC and 3D printing, validate with FEA and thermal checks, and make sure our batteries can survive the environments they’ll fly in.

This isn’t a “sit back and refine existing drawings” job. It’s a “build it from scratch” opportunity. From CAD to shop floor to production, you’ll own the mechanical side of making our batteries real.

What You’ll Do

- Collaborate with electrical, manufacturing, and software teams on complete battery systems

- Design thermally efficient, lightweight enclosures in SolidWorks

- Analyze structural integrity and environmental durability for airborne conditions

- Prototype with CNC, 3D printing, and shop tools to validate your concepts

- Optimize designs for thermal management, shock resistance, and manufacturability

- Contribute to project planning, risk assessments, and design reviews

- Document specifications, test results, and compliance data for certification

- Help set up mechanical design processes as we grow from prototype to production

What You Bring

- Bachelor’s or Master’s degree in Mechanical Engineering (or equivalent)

- 5+ years of experience in mechanical design, ideally for manufacturing/production

- Strong SolidWorks skills (assemblies, drawings, BOMs)

- A hands-on, no-nonsense mentality — you don’t just model, you build and test

- Knowledge of manufacturing methods (CNC, injection molding, sheet metal, extrusion)

- Experience with FEA and thermal analysis to validate designs

- Bonus: thermofluid knowledge or experience in battery systems

What We Offer

- Competitive salary between €4000 – €5.000 gross/month (based on experience)

- 38 paid days off per year based on full-time (25 vacation + 13 ADV via CAO Metaal & Techniek)

- 8% holiday allowance, travel reimbursement, and a pension via PMT

- A chance to own and build a critical part of our product and culture

- A fast-moving startup team that values autonomy, trust, and getting things done

- Coffee, smart people, and space to experiment — no corporate nonsense

Ready to Build Something That Matters?

If you’re the kind of person who likes figuring things out, making stuff work, and seeing your tests stop real-world failures before they happen — let’s talk.

Reach out to [email protected] with your CV or LinkedIn

Acquisition and recruiters: thanks, but not needed.