Tooling, workflows, processes — you make it manufacturable.

Before You Hit “Apply”

Tulip Tech is building its manufacturing backbone. Production is evolving from early assemblies toward stable, repeatable processes. There are no fully optimized workflows yet, and that’s exactly where you come in.

If you enjoy being close to the shop floor, improving how work is done, designing tooling, and turning early-stage assembly into reliable processes, this role is for you.

Your Mission

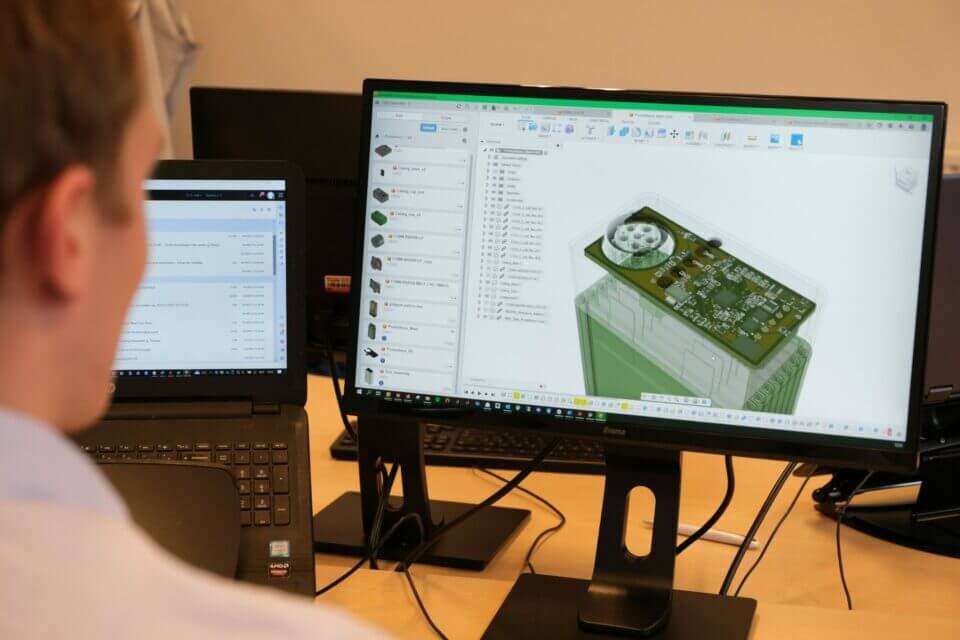

As a Process Engineer, you will design, implement, and continuously improve Tulip Tech’s manufacturing processes to ensure consistent, safe, and high-quality production of lithium battery systems.

You will focus on how products are built: defining assembly steps, tooling, and in-process controls that make daily production repeatable and robust.

You will be part of the production team, working closely with Manufacturing Engineers and the Production Manager. Together, you will build the process foundation that supports future scale-up.

What You’ll Do

- Define and optimize assembly processes, workstations, and task sequences

- Design, test, and improve jigs, fixtures, and tooling to increase repeatability and ergonomics

- Translate engineering designs into clear, executable manufacturing processes

- Create and maintain work instructions, SOPs, and process documentation

- Support daily production by troubleshooting process issues and deviations

- Analyze defects, rework, and bottlenecks and implement sustainable improvements

- Support pilot builds and process validation activities

- Work closely with engineering, quality, and supply chain to align processes

What You Bring

- 3+ years of experience in process engineering, manufacturing engineering, or industrialization

- Bachelor’s or Master’s degree in Mechanical, Industrial, or Systems Engineering

- Experience in small-batch or medium-scale assembly environments

- Practical knowledge of lean manufacturing, PFMEA, and basic quality systems

- Strong CAD skills and experience supporting design-for-manufacture

- Hands-on mindset and comfort working on the shop floor

- Bonus: experience with electronics, batteries, or electro-mechanical products

What We Offer

- Salary range: €4,000 – €4,500 gross per month, depending on experience

- 38 days off (25 vacation + 13 ADV via CAO Metaal & Techniek)

- 8% holiday allowance, travel reimbursement, and pension via PMT

- A key role in shaping how products are built in a fast-growing high-tech scale-up

- A pragmatic, international team that values ownership and execution

- Good coffee, smart colleagues, and a product you can be proud of

Ready to Keep Us Moving?

If you’re the kind of person who loves making supply chains flow smoothly and solving problems before they hit production — we’d love to hear from you.

Reach out to [email protected] with your CV or LinkedIn

Acquisition and recruiters: thanks, but not needed.