You build the system that makes scale possible.

Before You Hit “Apply”

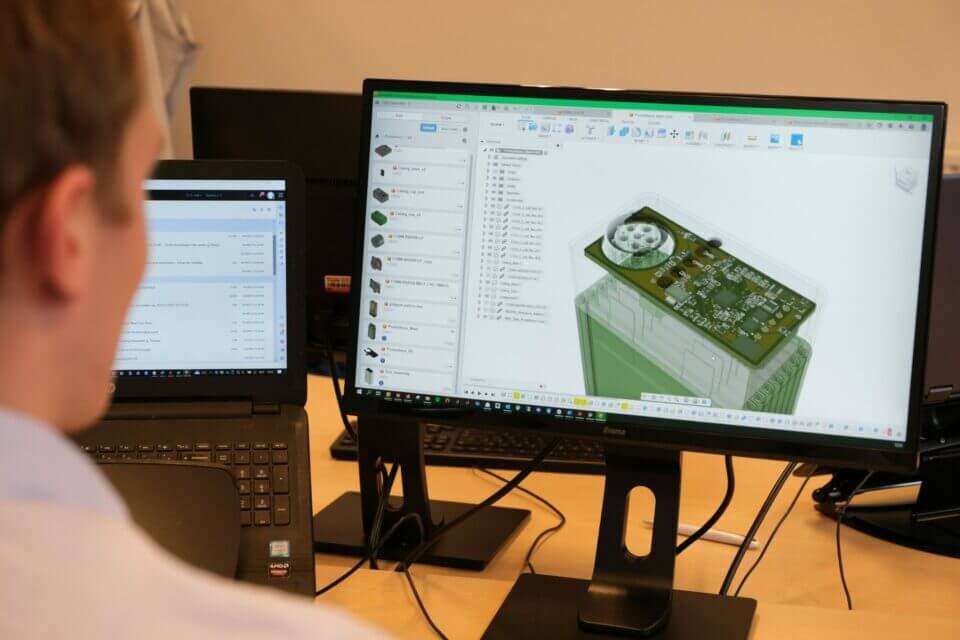

Tulip Tech is still building its manufacturing backbone. There are no rigid production lines — yet. You’ll help define processes, design tooling, and improve workflows. If you’ve worked in environments where getting your hands dirty is part of the job, and you like turning early-stage assembly into scalable systems, this is your chance to lead.

Your Mission

As a Manufacturing Engineer, you will design and scale Tulip Tech’s manufacturing system to support production volumes of up to 100,000 units per year.

You will own the manufacturing setup at system level: production strategy, line architecture, capacity, and scalability. You will work hands-on on the shop floor while also shaping the long-term production roadmap.

You will be part of the production team, working closely with other Manufacturing Engineers, Process Engineers, and the Production Manager. Together, you will build a robust, efficient, and scalable manufacturing operation.

What You’ll Do

- Design the overall production strategy and line architecture for scaling volumes

- Develop factory and line layouts, takt time models, and capacity planning

- Define production cells, material flow, and staffing models

- Select and validate tooling, equipment, and automation solutions

- Lead pilot builds, ramp-ups, and industrialization phases

- Ensure manufacturability at system level (DFM with R&D)

- Implement traceability, quality systems, and compliance requirements (ISO, CE, UN38.3)

- Drive continuous improvement in cost, yield, throughput, and reliability

What You Bring

- 3+ years of experience in manufacturing engineering or industrialization

- Bachelor’s or Master’s degree in mechanical, industrial or systems engineering

- Experience with small-batch or medium-scale assembly environments

- Familiar with lean principles, FMEA, and quality assurance systems

- Strong CAD skills and ability to collaborate on design-for-manufacture

- Bonus: experience in electronics or battery production is a pluss

What We Offer

- Salary between €4.000 – €4.600 gross/month (based on experience)

- 38 days off per year (25 vacation + 13 ADV via CAO Metaal & Techniek)

- 8% holiday allowance, travel reimbursement, pension via PMT

- A chance to shape manufacturing processes and scale production in a fast-growing tech startup.

- A tight-knit team that values initiative, trust, and getting things done

- Coffee, smart people, and a high-tech product to be proud of

Ready to Keep Us Moving?

If you’re the kind of person who loves making supply chains flow smoothly and solving problems before they hit production — we’d love to hear from you.

Reach out to [email protected] with your CV or LinkedIn

Acquisition and recruiters: thanks, but not needed.